The Ultimate DTF Printing Guide: Techniques, Materials, and Applications

The Ultimate DTF Printing Guide: Techniques, Materials, and Applications

Blog Article

Ultimate Guide to DTF Printing Strategies for Magnificent Textile Layouts

Embarking on the trip of mastering DTF printing techniques can open up a globe of opportunities for producing aesthetically captivating textile layouts. In this overview, we will explore the intricate information of DTF printing, from comprehending the essential basics to unraveling progressed shade methods that can elevate your layouts to new heights.

Understanding DTF Printing Essentials

DTF printing, a procedure that entails transferring layouts from a special film to fabrics using warm and stress, develops the structure of textile printing techniques. The initial step in DTF printing includes developing or selecting a style that will certainly be published onto the textile.

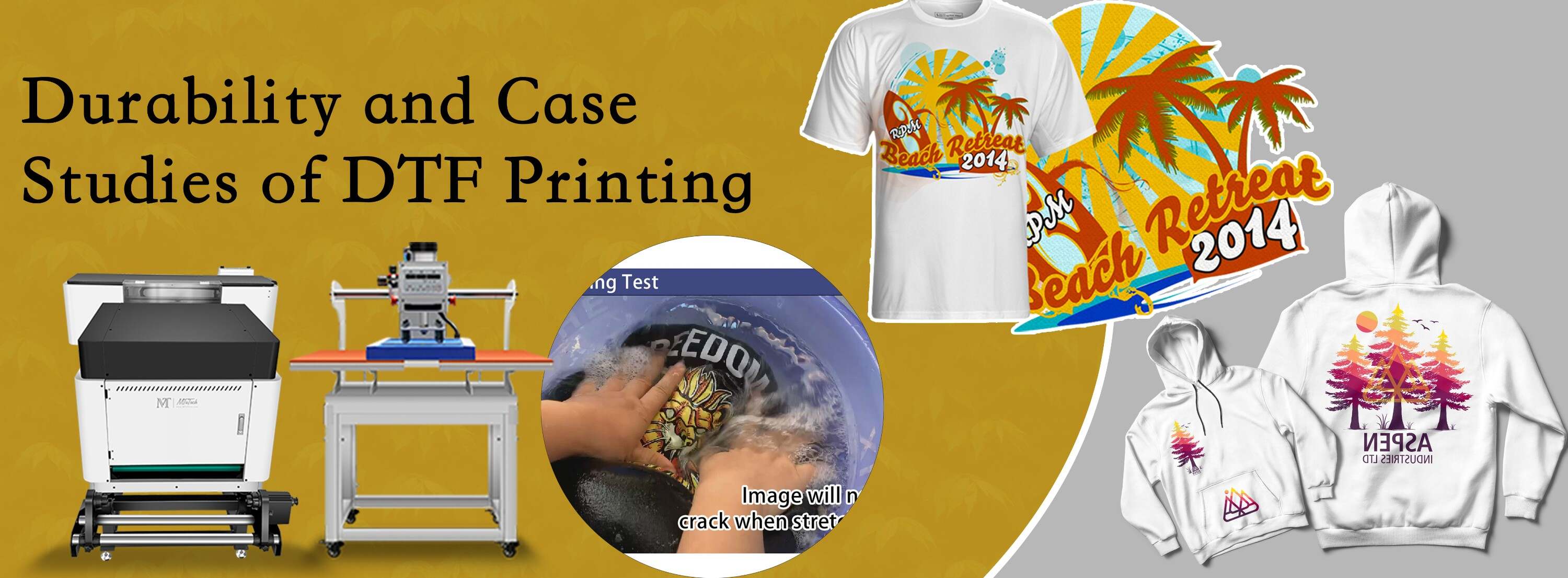

Once the design is printed on the movie, it is then carefully put onto the textile, ensuring appropriate placement and positioning. The next important action involves applying warm and stress making use of a heat press device. This procedure turns on the dyes or pigments on the movie, causing them to sublimate and bond with the material fibers completely. The last outcome is a stunning, resilient fabric design that is washable, versatile, and resistant to fading. In general, recognizing the essentials of DTF printing is essential for mastering this contemporary textile printing method.

Picking the Right Fabric Products

Having developed the foundational concepts of DTF printing techniques for textile layouts, the next essential consideration exists in choosing the ideal textile products to complement this ingenious procedure efficiently. In addition, the stretchability of these materials can fit the warmth transfer process included in DTF printing without misshaping the design. By choosing the appropriate textile materials, developers can take full advantage of the possibility of DTF printing to create lasting and sensational textile styles.

Mastering the Printing Refine

To excel in DTF printing techniques for textile designs, grasping the printing procedure is crucial for attaining top notch and constant results. The temperature, stress, and period of warm application have to be thoroughly managed to make sure correct attachment of the style to the textile. By refining each of these actions in the printing process, developers can regularly generate long lasting and stunning textile layouts with DTF printing techniques.

Enhancing Layouts With Color Methods

In addition, explore color read what he said slopes can bring a sense of movement and fluidity to the style. By mixing colors flawlessly, a slope result can be achieved, including a vibrant and modern-day touch to the fabric style. Furthermore, making use of shade blocking methods can develop vibrant and striking visuals by comparing various solid colors in distinct areas of the layout.

Moreover, incorporating metal or neon colors can provide a unique and eye-catching aspect to the textile layout, making it stand out and emanate a sense of vibrancy. When strategically used, these color strategies can raise the overall visual appeal of fabric styles, making them more exciting and unforgettable.

Troubleshooting Common DTF Printing Issues

After exploring numerous color strategies to improve fabric styles, it is necessary to attend to common DTF printing concerns that may emerge during the manufacturing process. One usual issue is inadequate adhesion, which can arise from improper treating temperature levels or times. To settle this issue, ensure that the treating settings are precise which the sticky made use of appropriates for the details fabric being printed on. Another regular obstacle is shade disparities, where shades may appear differently than anticipated. This can be triggered by why not try here inaccurate shade accounts or settings in the printing software application. To tackle this, double-check the color settings and accounts to guarantee they match the intended design. Furthermore, concerns with image clarity and sharpness can happen as a result of low-resolution images or improper printing methods. To resolve this, constantly use premium pictures and change the printing setups for optimum quality. By knowing these common problems and executing the needed troubleshooting actions, you can boost the total top quality of your DTF published fabric styles.

Verdict

In final thought, mastering DTF printing methods is important for developing spectacular fabric designs. With method and attention to detail, one can develop stunning and one-of-a-kind textile styles making use of DTF printing techniques.

Layouts))))

DTF printing, a process that includes moving designs from a special movie to fabrics making use of heat and pressure, develops the structure of textile printing methods.Having actually developed the foundational principles of DTF printing strategies for fabric designs, the next essential consideration lies in choosing the ideal textile products to complement this ingenious procedure effectively. By choosing the ideal fabric products, developers can maximize the capacity of DTF printing to produce sensational and long-lasting textile styles.

To stand out in DTF printing strategies for fabric layouts, understanding the printing procedure is essential for achieving consistent and premium outcomes. DTF Printing. By refining each of these actions in the printing procedure, developers can constantly create sensational and long lasting fabric styles with DTF printing methods

Report this page